A revolutionary solar technology developed in Australia, designed to assist photovoltaic (PV) manufacturers in detecting faults in solar cells, is generating significant interest from three of the world’s four largest solar manufacturers, according to its creators.

This novel technology offers a contactless approach for identifying faults within solar cells and originates from the “ACDC” research group at the University of New South Wales (UNSW), a prominent name in the realm of PV technology.

Commercialisation and Industry Interest

The technology is being commercialised by BT Imaging, a company that has established ties within major global solar cell manufacturers and was spun out from the university in 2007. A recent press release from UNSW, which announced a £1.4 million deal for commercialisation between both parties, suggested that this technology “could soon become the new global standard in solar cell testing”. UNSW’s project leader, Ziv Hameiri, reaffirmed that such excitement is not unfounded.

“Discussions are already underway with three of the four leading companies worldwide. They have begun evaluating this capability and its effectiveness,” Hameiri stated to Renew Economy. He added, “While it may sound ambitious, these firms are genuinely thrilled about this technology. Once one or two of them adopt it, we anticipate the rest of the market will soon follow suit.”

Addressing Existing Challenges

The technology addresses a significant issue: the current testing methods are outdated, having persisted for over a decade, whilst solar cells have undergone substantial advancements in that time. Presently used current-voltage testers must make contact with solar cell surfaces, risking damage, and can only perform checks post-metallisation, when conductive metal contacts are applied to the cell.

This limitation means that faults occurring earlier in the manufacturing process often go undetected, and the existing methods struggle with newer cell technologies, including tandem solar cells. The new approach combines innovation with artificial intelligence and builds upon the photoluminescence tools previously trialled with perovskite solar cell manufacturer Caelux in 2023.

How the New Technology Works

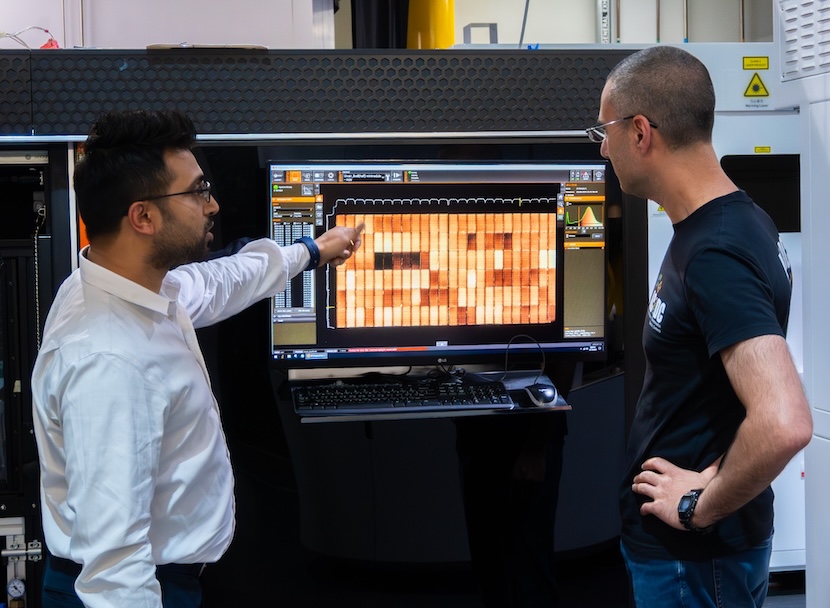

The innovative system employs a camera that captures the peaks and intensity of electroluminescence and photoluminescence emitted when solar cells are illuminated. This enables precise readings on voltage, series resistance, and efficiency. Through an algorithm, these measurements are mapped, allowing classification of cells based on quality and insights on the potential origins of defects, alongside recommendations for corrective measures.

Moreover, this method can be applied throughout various stages of the production process, making it possible to rectify or discard faulty cells before significant resources are invested in them. Electroluminescence testing is already utilised within parts of the solar industry to verify that modules remain intact during shipping and after installation.

Stay updated with the latest developments in clean energy by subscribing to our free daily newsletter, joining over 27,200 others keen on staying informed.