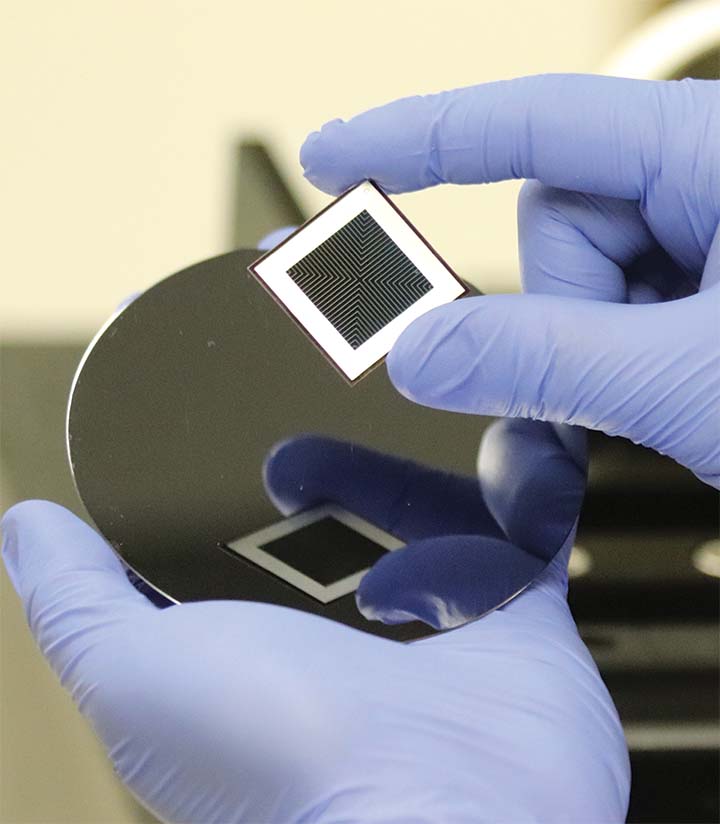

Australia has become well known for its solar power, the long, hot summers and vast open spaces that provide ideal conditions for capturing the sun – with solar photovoltaics (PV) leading the way in the grid’s renewable uptake. This year, the Australian National University (ANU) revealed a new breakthrough in solar power technology; a record type of bifacial solar cell incorporating laser doping technology.

Bifacial solar boasts dual-sided solar cells, which means both the front and back of the cell can generate power. Bifacial solar is gaining traction worldwide, growing in popularity due to its higher efficiency, lower cost and higher generation capacity.

According to Wood Mackenzie, a global research and consultancy business that focuses on natural resources, bifacial solar capacity grew from 97MW globally in 2016, to over 2,600MW in 2018 and 7000MW in 2019 – with bifacial modules set to account for 17.2 per cent of solar market share by 2024.1

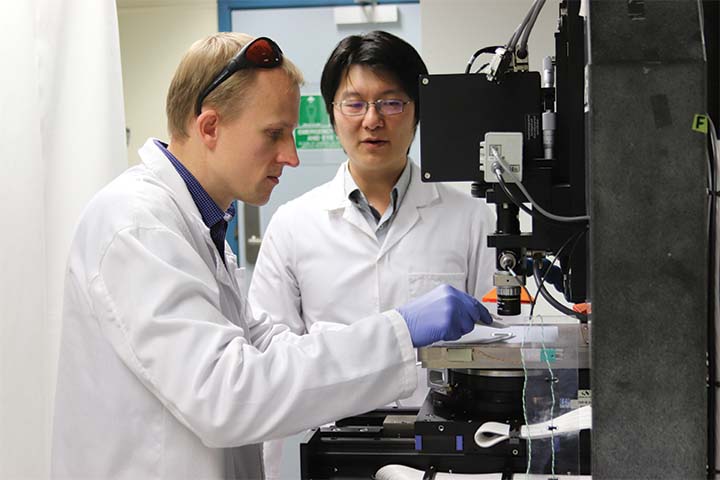

As this new technology started to grow in popularity, scientists at the Australian National University (ANU) were working on producing a highly efficient type of solar cell using laser processing.

ANU Project Principal Investigator, Dr Kean Chern Fong, said the idea behind the project, which took three years to complete, started back in 2016 when bifacial solar cells were first making their way into commercial products.

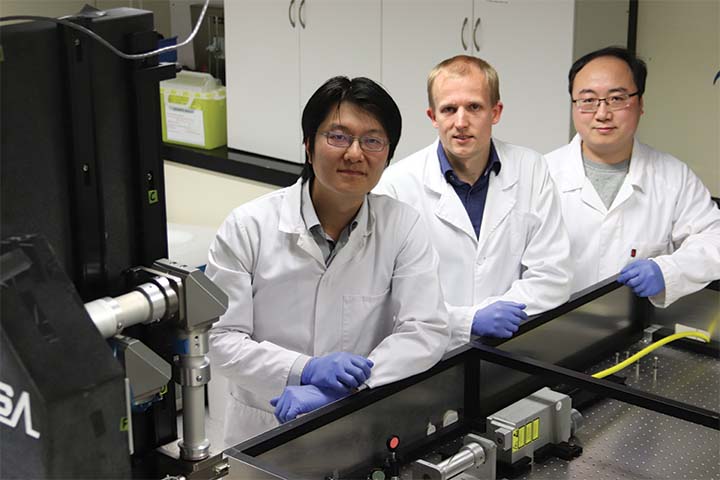

The project that has now led to Dr Fong, and his fellow ANU scientists, Dr Marco Ernst, Project Investigator, and Dr Wensheng Liang, a postdoctoral research scientist, developing an innovative new bifacial solar cell with record efficiency.

“This is a world record for selectively laser-doped solar cells and among the highest efficiency bifacial solar cells,” Dr Fong said.

Project beginnings

A team of research scientists at ANU led by Dr Fong initiated the idea of developing a bifacial device using Australian-developed technologies, this attracted the attention of several industry partners, and led to the project being funded by ARENA to execute the planned technology development.

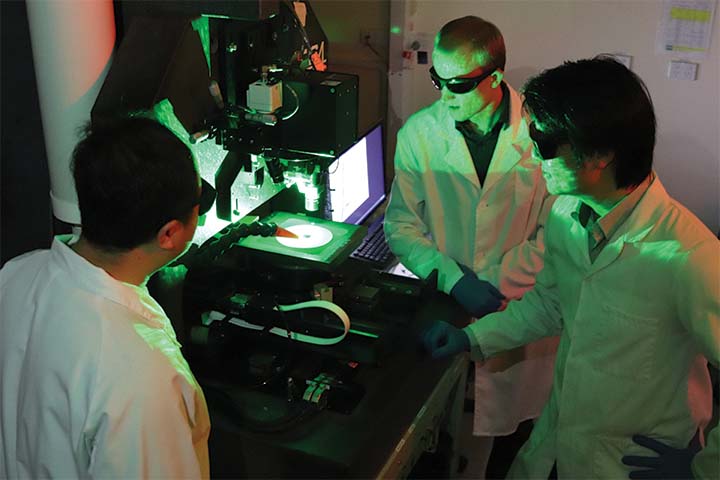

“The resulting outcome of the project was exceptional, facilitating the advancement of numerous enabling technologies, such as transparent film deposition, laser processes, and polysilicon contact technologies along the way towards the eventual demonstration of the record bifacial solar cell,” Dr Fong said.

The bifacial solar cells were developed by a team of expert Australian researchers with experience in similar technologies.

The independently measured performance of 24.3 per cent with a bifacial factor of 96.3 per cent represents the highest power conversion efficiency of any single-junction Si device incorporating laser selective doping.”

The process of laser selective doping uses very short nano-second pulses of laser to blast phosphorus dopants into the silicon material, allowing precise control of the doping depth and location.

Dr Fong said this is an improvement over conventional furnace baking, which is also known as the diffusion process. “We have developed what I would call a true bifacial solar cell, as it has nearly symmetrical power generation capacity on both surfaces of the device,” Dr Fong said.

“When deployed on a conventional solar farm, a bifacial cell absorbs direct incoming light, while also taking advantage of ground reflection, which can contribute up to additional 30 per cent power generation.

“Bifacial solar cells are becoming increasingly important in the roll out of solar farms and are expected to have a market share of over 50 per cent in the next five years. “Our work demonstrates the incredible capabilities of this technology.”

The technology development roadmap

Dr Fong said that once the project had begun in 2017, they created a team of high-caliber Australian researchers who had prior knowledge and experience in various technologies in the field.

The project boasted a comprehensive technology development plan from the very beginning, with the team heading into the project with a roadmap of technologies that had to be developed for the final design.

Technological developments for the project included:

» A new laser process was necessary to offer local selective doping, where phosphorus dopants are blasted into specific locations on the silicon with great precision – as opposed to conventional baking the silicon wafer

» A metal contact scheme was necessary on the rear surface to allow light passage

» A novel film with multi-functional capabilities was needed to minimise reflective losses, maximise photon capture, and retention of electrons all at once

“The extensive project planning and technology development cycle draws from previous experience in ARENA funded industry linked projects, which is a testament to the importance of continuity in research funding,” Dr Fong said.

“The breadth of our collective knowledge is the key towards the projects’ success; due to the need for technology development in numerous areas that would come together as building blocks in the final envisaged design.”

How is it so efficient?

Bifacial solar is highly efficient for a few reasons, the most obvious is more generation in a small area; double the panels and the capacity of generation is obviously going to increase.

They are also more efficient due to ground reflection or surface reflection, referred to as albedo (ground reflected light), which, as stated by Dr Fong, can contribute up to an additional 30 per cent power generation. Dr Fong explains that the reflection off different surfaces offer differing levels of albedo.

“The intensity of ground reflection is around 20 per cent on grass and most crops, 40 per cent on concrete, and is as high as 80 per cent from fresh snow. Especially relevant to the Australian climate, albedo reflection off arid desert sand offers about 30-40 per cent of

albedo,” Dr Fong said.

“Therefore, no special treatment is necessary in most sites to take advantage of the extra power generation from bifacial modules.

“Adoption of bifacial technology accelerated at an exponential rate over the last few years, and the key reason being that it is a technology that simultaneously promises higher performance at a lower cost.”

Long-term affordability

Bifacial solar may come with more upfront costs initially, but it offers significant savings once fully operational. Dr Fong said this is because the most expensive single cost in conventional and PERC solar cells is the silver content within the metal paste, which covers the entire rear surface of the device, with bifacial solar cells inherently necessitating the use of metal fingers on the rear to enable rear light transmission.

“While this initially requires some specialised technology development, once the technology is in full production, it offers a significant saving in silver usage and therefore cost reduction,” Dr Fong said.

Bifacial solar is also becoming cheaper, as the cost was higher initially due to the slow progression of front and rear glass-glass technology.

“However, with its economies of scale, the cost of glass-glass modules is now on par with plastic rear sheets. Furthermore, glass-glass module offers better long term performance as glass does not degrade, and offers better protection against the elements,” Dr Fong said.

Bifacial technology and storage capacity

A concern regarding the greater power generation capacity of bifacial solar, and various renewables as they enter and become more common in the National Electricity Market (NEM), is that they may require greater storage capacity.

Dr Fong explains that grid level storage capabilities are already being considered and built within Australia in the form of batteries and pumped hydro, and that is a crucial step towards having a 100 per cent renewable energy grid.

“Building PV farms is a fairly matured exercise. Thanks to the advancements in meteorology and PV farm power output modelling, the power generation of PV plants is predictable within a reasonable range.

As with all PV farms, bifacial or otherwise, the system would have been designed with specific peak, and average annual power output even before the first panels are laid down,” Dr Fong said.

Challenges faced

The project, no matter how well planned, was not immune to the year of unprecedented events that 2020 and 2021 brought upon Australia.

“The period starting from the end of 2019 right up to the end of the project was indeed an especially challenging time where we faced numerous lengthy laboratory closures due to the bush fires, hailstorm damage, and COVID-19 restrictions,” Dr Fong said.

“This caused numerous delays and financial constraints within the project but was eventually successful through the support of ANU and the funding agencies.”

The future of bifacial solar

The future of bifacial solar in Australia is looking positive, with highly efficient, low cost and green power potentially on the horizon nation-wide.

“The ANU developed laser doped bifacial cell provides a novel method of device fabrication that provides an improvement over existing products in the market,” Dr Fong said.

“With the right industry partners to commercialise this design, we can further improve module panel efficiency, while simultaneously pushing down the costs.”

Dr Fong said that the need to create high efficiency at a low cost is key when it concerns residential PV or home solar, and is especially crucial in Australia – where residential installations make up over half of all installed PV panels in 2020.

“This work has been made possible due to the unrelenting support from the School of Engineering at ANU, and our funding agencies ARENA and ACAP, all of which has contributed financially to the project, but more importantly have played a major role in nurturing forward-thinking research scientists, which are and will continue to be the most valuable assets in our scientific community,” Dr Fong said.